pipe beveler

pipe chamfering machine

Category: pipe chamfering machine

Detailed Information

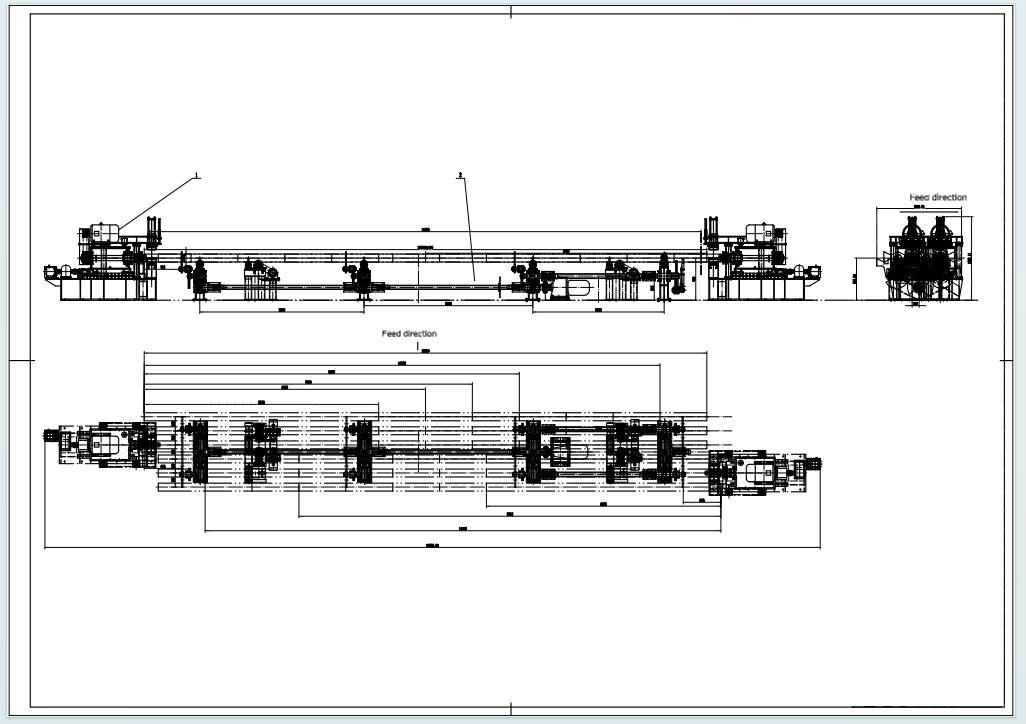

Steel tube flat chamfering machine

1. Pipe flat Chamfering machine equipment composition:

1.1 Cross-moving pipe taking equipment, take 1 pipe from the material bed at a time, send it to the left push-up station and the left groove station, carry out the push-up and groove process, and remove it after the groove ends.1.2 groove host with clamping system

1.3 equipped with clamping dies of various specifications and gear plates in charge.

2. Working parameters (customized as required) The following are sample parameters:

2.1 outer diameter of flat head inverted edge steel pipe: 25mm ~ 159mm, wall thickness 2.5-25mm, material maximum X70, tube length 5-12m.2.2 Outside Chamfering groove angle can be within 30-35 ° range.

2.3 production line speed: 5-20 PCs/hour.

3. pipe beveler Power configuration:

3.1 motor power:

|

Name |

Spindle motor |

feed servo motor |

Thrust motor |

Stepping and traverse reduction motor |

Electric control |

Total power |

|

Power |

30KWX2 |

5.5KWX2 |

1.1KWx4 |

18.5KW |

2.5KW |

96.4KW |

3.2 reducer speed ratio and clamping cylinder:

|

Name |

into the knife |

Push flush x4 |

Clamping cylinder X2 |

Stepping traverse reduction ratio |

|

Power |

1:20 |

1:35 |

Φ140X200 |

1:71 |

4. pipe beveler Working time sequence:

4.1 working time sequence: adjust the base height of the fixed fork in advance.Material bed -- step and move the fork to raise, take a steel pipe and move a station horizontally -- move the fork down -- push up, flat head clamping station -- clamp, flat head, withdraw knife, loose clamp -- step and move the fork to lift the steel pipe -- translate -- move the fork down and return to the original position, step and move the fork horizontally with 5 steel pipes.

5.2 Single-cycle time: push-up to parallel jobs, not taking up time alone, rising-horizontal shift-clamping-flat end completion-loose clip-rising-horizontal shift cycle. Efficiency calculation: flat head speed is 6-18 pieces/hour.

5. pipe beveler Brand of purchased parts:

5.1 feed servo motor 5.5KW servo motor5.2 spindle motor 30KW 6 grade, YE3 efficient energy-saving motor

5.3 Reducer: use Hengchen reducer, SEW reducer, FLENDER reducer, Bang Feili Reducer

5.4 Frequency Converter: spindle motor speed control, Weichuang frequency converter

5.5 bearings: Shaft, K2, FAG/INA, NSK

5.6 hydraulic system, Yuci brand, Bosch Rexroth, Danfoss and Kawasaki Heavy Industries, clamping with two independent hydraulic station respectively.

5.7 control system, using Xinjie PLC and Buke touch screen, network cable communication control.

5.8 Electronic Control Components, Schneider brand, ABB, Siemens

HOME

HOME