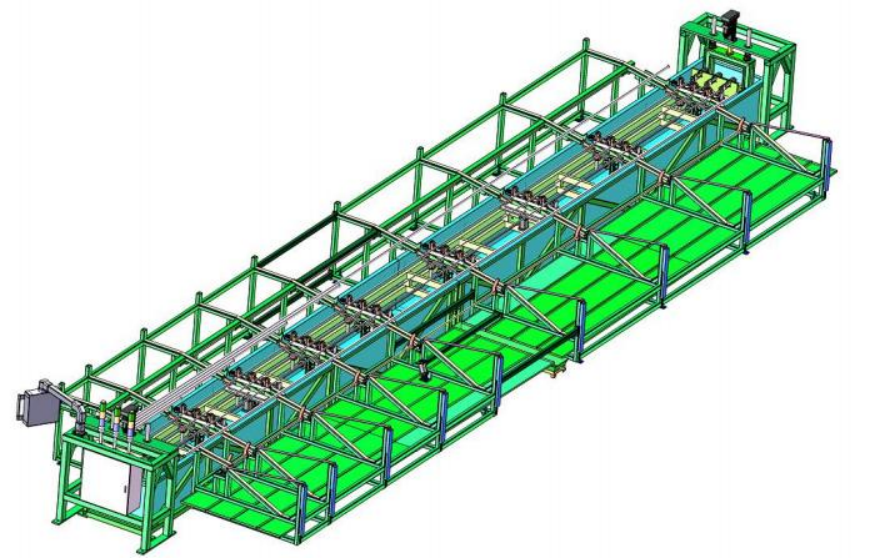

Hydrostatic testing machine

pipe pressure testing machine

Hydrostatic testing machine

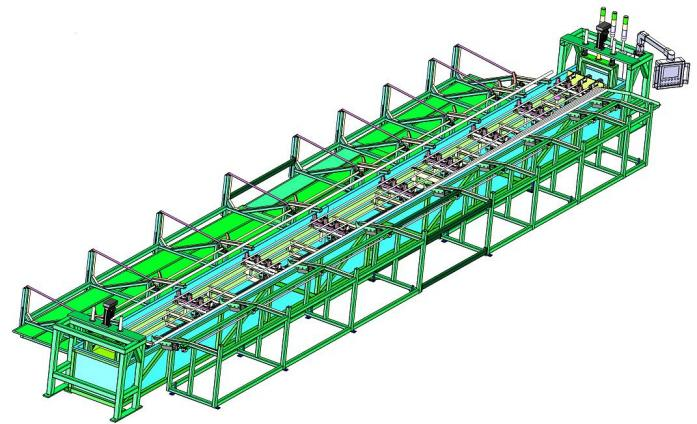

The inspection platform consists of lift platform racks, automatic head sealing device, automatic feeding and blanking device, and automatic clamp pipe device.

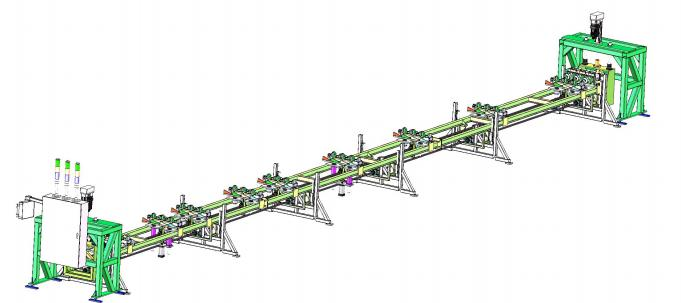

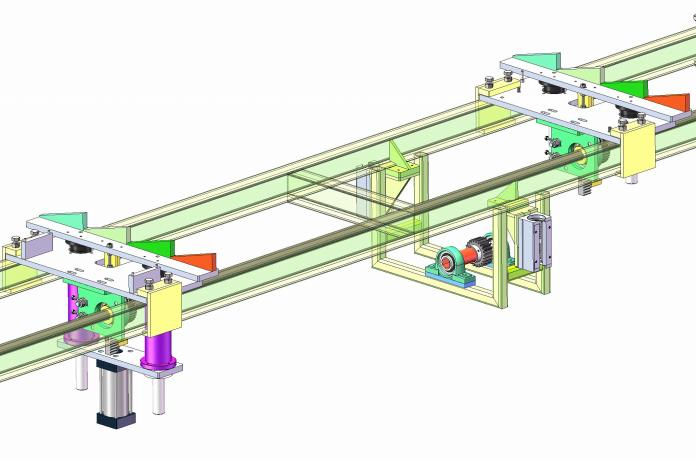

I. Hydrostatic testing machine Lift platform stand

1. The bench is made of national standard SUS304 stainless steel 10# I-beam steel, which ensures the rigidity of the bench and prevents the bench from rusting, bending,

Deformation.

2. Hydrostatic testing machine Lift platform the lifting of the bench is synchronously lifted by servo electric cylinder, and the bottom of the bench is synchronously designed by synchronous hexagonal axis + gear rack. Gears are installed on the rotating shaft, and the rack is fixed at the bottom of the box bottom bracket, when the platform is raised and lowered, guiding shaft and the gear passively follow the rotating motion, and the gear moves up and down along the fixed rack to push the middle part of the platform to rise and fall synchronously, so as to achieve the overall synchronization of the platform's lifting and falling, preventing the platform from bending

Variant

3. On both sides of the platform, there are sbr semi-open stainless steel linear bearing guides to prevent the front, back, left and right deviation and jumping division during the lifting process of the bench.

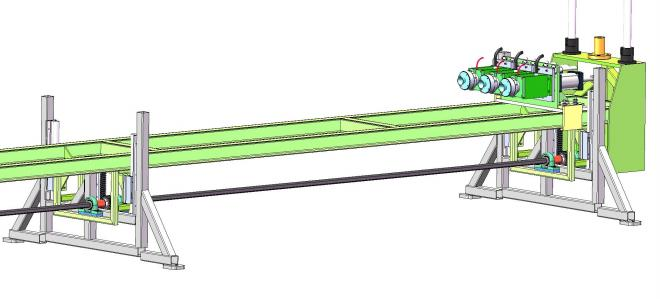

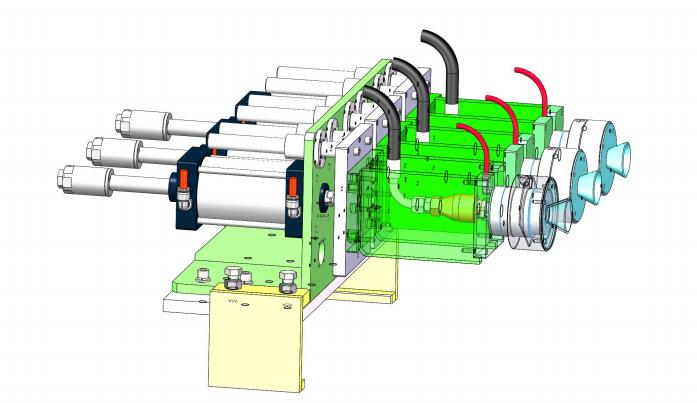

II. Hydrostatic testing machine Automatic head sealing device

2.auto matic hea device

The automatic head sealing device adopts radial seal design, driven by stainless steel adjustable cylinder, both sides of the end of the pipe are seal head front and rear movement set into the pipe head, seal head sealing ring ventilation radial pressure clamp pressure test pipe fittings, after the tail high-pressure trachea is ventilated and pressurized to the set pressure value, keep the pressure,

The pressure test completes the pressure relief of the hair pin pipe high-pressure Assembly, the seal head exhaust releases the pipe fittings, and the stainless steel cylinder returns to complete the pressure test process,

1. The Plug device consists of two groups on the left and right, of which one side near the control cabinet is the fixed end and the other end is the mobile end. When the pipe length specification changes, you only need to adjust the position detection of the mobile end to adapt to pipe specifications of different lengths. Plug device clamp fixed design, simple adjustment

It is quick.

2. The upper and lower stainless steel linear bearings of the seal head cylinder are guided and retractable to prevent seal head seats from falling and shifting due to gravity.

3. Hydrostatic testing machine The cylinder is 304 stainless steel adjustable cylinder. When the short stroke tolerance is short, the plug seat cannot be moved, and only the telescopic stroke of the cylinder needs to be adjusted.

4. Seal head adopts offline overall quick-change structure design, made of stainless steel 304, high-pressure air pipe and low-pressure air pipe are quickly connected to street replacement

Rice noodles are simple and fast.

5. Stainless steel trumpet guide design of sealing head. When the pipe head is slightly bent and deformed, trumpet can be slightly corrected and guided to make the pipe head smooth

Enter the inside of the sealing head without scratching the radial sealing ring, thus reducing the vulnerable cost of the sealing ring.

III. hydrostatic pressure tester Automatic feeding and blanking device

1. hydrostatic pressure tester The automatic feeding and blanking device consists of multiple sets of 304 stainless steel cylinders + pipe jacking triangular plate, and adopts double guide rod chrome-plated rod +304 stainless steel straight line

Bearing guide ensures the stability of lifting and reduces the probability of rust and stuck by guide rod.

2.hydrostatic pressure tester The lifting mechanism is designed synchronously by synchronous hexagonal axis + gear rack. The gear is installed on the rotating shaft, and the rack is fixed on the head of the cylinder of the box. When the cylinder is retractable, guiding shaft and the gear passively follow the rotating motion, drive other groups of lifting mechanisms to move synchronously, ensuring the same loading and unloading

Step.

3. hydrostatic pressure tester The lifting fixed seat adopts the buckle design, the bottom connecting shaft is stainless steel hexagon bar, the Gear bearing and hexagonal bar are installed for activities, and the pipe length is long.

When the degree changes, the fixed seat can move a certain distance horizontally to adapt to the length of the pipe.

4. hydrostatic pressure tester The triangular top plate of the upper and lower material pipe is made of nylon rubber sheet to prevent scratching the surface of the pipe.

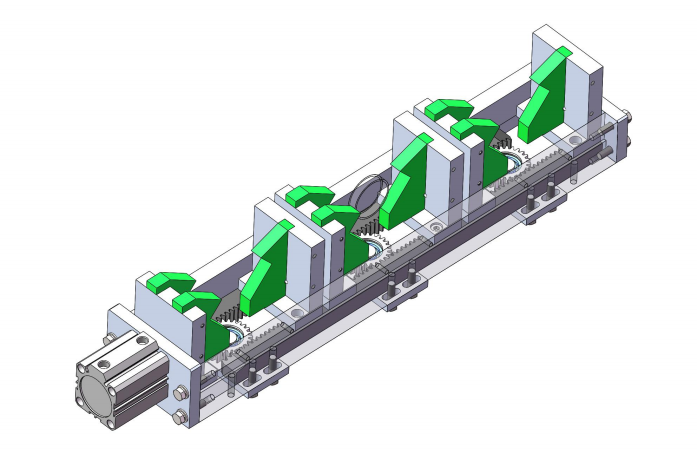

IV.hydrostatic pressure tester Automatic clamp pipe device adopts synchronous clamping design of cylinder drive rack gear, cylinder telescopic time double <shaped plywood inward clamping, the clamped pipe automatically centering with seal Head Center, there is no need to adjust the pipe position when the pipe specification changes. Prevent when the plug cylinder is sealed

Axial bending displacement of pipe.

1. Clamping cylinder, gear rack, bearing and screw are all made of SUS304 stainless ste

2. The shaped clamping plate is made of nylon rubber to prevent scratches on the pipe surface.

3. The pipe clamp is fixed to the top of the automatic loading and unloading pipe jacking device, eliminating the need for separate adjustment when the pipe length changes.

Partial diagram of the hydrostatic pressure tester

HOME

HOME