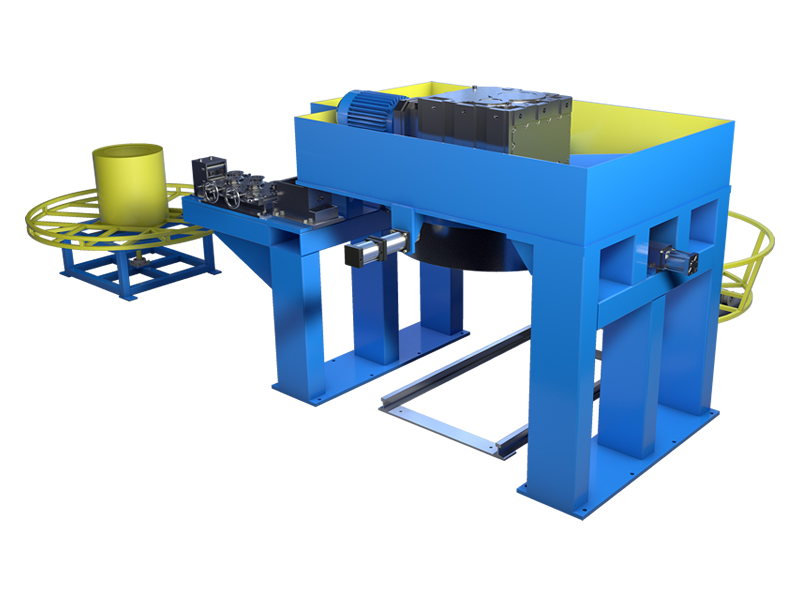

AutoSeamless Triple-Draw Pipe Machine

Seamless pipe making machine

Automatic multi-line cold drawing machine composition and features:

The cold dial machine mainly consists of feeding bench, receiving trough bench, Rod pushing device, core rod lifting platform frame, mandrel front and rear adjustment device, pull die seat, bed body part, drawing trolley, main transmission device, discharge conveying chains device, automatic finished product collection rack, etc.When the detection device on the feeding platform does not detect the tube blank when the drawing starts, the lifting material frame rises to roll the tube blank to block the material retaining device. When the detection device detects the tube blank, the lifting material frame automatically drops, the receiving trough rises upper baffle, and the rack and set-top devices device automatically distribute the tube blank into the receiving rack receiving trough. The receiving trough has a certain inclination, and the receiving trough is equipped with a roller, which rises through the cylinder, roll the tube blank to the baffle to block it. At this time, the pressing cylinder pushes out and presses the tail of the tube blank, at this time, the core rod lifting platform frame rises to the center position of the rod. The first stroke cylinder on the core rod seat pushes out and passes mandrel to the inner hole of the tube blank, and the tube blank is quickly put on the core rod by trolley for carrying materials on the receiving bench, after the core rod lifting platform frame is worn, it drops to the Drawing Center line. At this time, the first stroke cylinder automatically pushes out the three cylinders, core rod, mandrel and tube blank pull head on the skateboard through the drawing die hole together, at this time, after receiving the first stroke in place control signal, the drawing trolley, which has been waiting while the drawing die is sitting, pushes wrench jaw cylinder to clamp the tube blank head, and the main motor starts to drive wrench jaw to the sprocket chain, drive the trolley to pull out, and at the same time, the second stroke cylinder is also pushed out and started to pull out. At this time, the upper cylinder of the bed body lifting device is pushed out, and the to connect material device is pushed to the upper edge. After the drawing is completed, the steel pipe drops on the lifting to connect material device. Up and down, at this time, the conveying chains action on the discharge conveying chains device, when it drops to conveying chains, the quality control will roll down to the automatic falling collection rack, and the aggregate rack is equipped with a detection platform, when testing the finished pipe, use the button to control the cylinder to push the detection platform to the flat position for detection, and at the same time, pull the trolley and quickly return to the drawing die sitting side to wait for the next automatic logic work.

Features:

1. This equipment can draw carbon steel pipe, bearing steel, low alloy steel, stainless steel, copper molybdenum and various non-ferrous metals.

2. The whole machine adopts the latest and simple design of the current rolling process, which is easy to operate, reduce maintenance and convenient to maintain.

3. The cold drawing machine bed body adopts double-chain C- frame structure, and the chain center is consistent with the Drawing Center.

4. The spherical design of the pull die base makes it easy to straighten.

5. It is convenient to replace the drawing trolley with wrench jaw.

6. The main drive adopts DC motor, which is energy-saving and stable.

7. The whole machine adopts PLC automatic control, and the whole line has the display of various parameters, various safety interlocking and alarm functions.

8. Each pass achieves ideal reduction rate and pipe wall deviation correction.

9. The inner and outer diameter and wall thickness can obtain extremely high required tolerance requirements and roughness.

Automatic single chain three line cold drawing machine technical parameters:

|

Serial Number |

Project Name |

Unit |

LB-15T-3 |

LB-20T-3 |

LB-30T-3 |

LB-45T-3 |

|

1 |

Outer diameter of tube billet |

mm |

Φ8-Φ18-(32) |

Φ8-Φ20(32) |

Φ9-Φ32(42) |

Φ19-Φ68 |

|

2 |

billet thickness |

mm |

0.8-3 |

0.8-3.5 |

0.8-3.5 |

0.8-4 |

|

3 |

Finished tube outer diameter |

mm |

Φ5-Φ12.7(25.4) |

Φ5-Φ15(28) |

Φ6-Φ25(38) |

Φ16-Φ60.5 |

|

4 |

Wall thickness of finished pipe |

mm |

0.5-2.5 |

0.5-3 |

0.5-3 |

0.5-3.5 |

|

5 |

Pull Count |

Support |

1, 2, 3 |

1, 2, 3 |

1, 2, 3 |

1, 2, 3 |

|

6 |

Maximum total drawing force |

KN |

150 |

200 |

300 |

450 |

|

7 |

Drawing speed |

m / Min. |

0-6 (stepless speed regulation) |

0-8 (stepless speed regulation) |

0-10 (stepless speed regulation) |

0-8.5 (stepless speed regulation) |

|

8 |

Pulling trolley return speed |

m / Min. |

40 (adjustable) |

40 (adjustable) |

40 (adjustable) |

40 (adjustable) |

|

0 |

Rod wearing speed |

m / Min. |

0-50 |

0-50 |

0-50 |

0-50 |

|

10 |

Main motor power |

KW |

30 |

35 |

75 |

75 |

HOME

HOME